Automation in Electrical Installations: Benefits and Current Trends

Automation in Electrical Installations is transforming the way companies manage their energy systems. Thanks to advanced technologies like PLCs (Programmable Logic Controllers) and SCADA systems (Supervisory Control and Data Acquisition), electrical installations are now more efficient, secure, and adaptable to the challenges of the modern world. This article explores how automation drives these benefits and what trends are shaping the future of the industry.

1. What is automation in electrical installations?

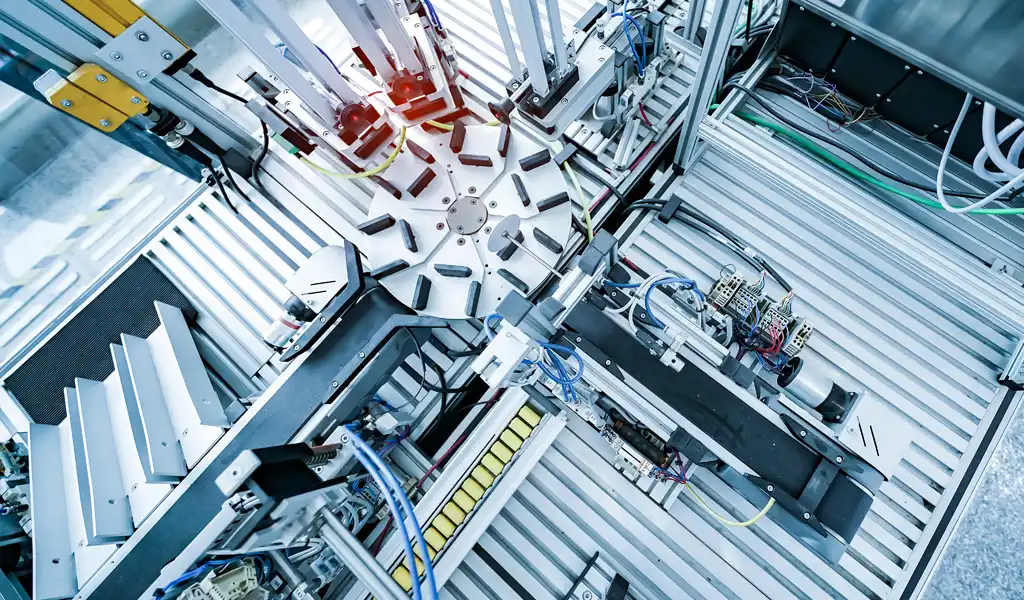

Automation in electrical installations involves the integration of systems and technologies that allow for monitoring, controlling, and optimizing the operation of electrical systems automatically. This minimizes human intervention, ensuring more precise and reliable processes.

Automated systems collect real-time data, process it, and execute specific actions, such as activating circuits or adjusting energy consumption based on demand.

Practical example: In a factory, an automated system can turn off non-essential equipment during peak consumption times, reducing energy costs and preventing overloads.

2. Benefits of Automation in Electrical Installations

Automation provides multiple advantages for both industries and small businesses. The main benefits include:

2.1. Improvement of operational efficiency

- Optimization of energy consumption: Automated systems adjust energy use according to real needs, preventing waste.

- Continuous processes: Solutions like SCADA allow for real-time monitoring and adjustment of electrical systems, minimizing disruptions.

- Reduction of response times: Thanks to PLCs, critical operations are executed faster and with greater precision.

2.2. Increase in safety

- Constant monitoring: Sensors and automated systems detect anomalies (such as overheating or electrical leaks) before they become serious issues.

- Advanced protection systems: Automation integrates devices like smart circuit breakers that automatically respond to electrical faults.

2.3. Savings in operational costs

-

Less dependence on labor: Automation reduces the need for constant manual supervision.

-

Predictive maintenance: Automated systems can anticipate failures based on historical data, enabling more efficient maintenance.

3. Key technologies in electrical installation automation

3.1. SCADA systems

3.2. PLCs (Controladores Lógicos Programables)

PLCs are industrial computers that control specific processes in real-time.

- Reliability: They are ideal for industrial environments with harsh conditions.

- Flexibility: They can be programmed to perform specific tasks, such as turning equipment on or off automatically.

3.3. Smart sensors

Sensors collect data such as temperature, current, and voltage, providing real-time information to adjust the electrical system.

- Early fault detection: They prevent breakdowns by proactively identifying anomalies.

- IoT integration: They connect to cloud-based platforms for advanced analysis.

4. Current trends in electrical automation

The electrical installation automation sector is rapidly evolving. Some of the most notable trends include:

4.1. Internet of Things (IoT)

IoT connects devices and systems to share data and optimize their operation. In electrical installations, this means:

- Predictive analysis: Detecting issues before they occur.

- Remote management: Operating and adjusting systems from any connected device.

4.2. Artificial Intelligence (AI)

4.3. Sustainability

Automation aligns with the transition to renewable energy sources, integrating solar panels and smart storage systems.

5. Safety and sustainability

Safety is a fundamental pillar in any industrial electrical installation. Best practices include:

- Implementing protection measures: Such as differential switches and grounding systems.

- Staff training: Training operators in the safe handling of electrical systems.

- Sustainability: Incorporating energy-efficient solutions, such as LED lighting and solar panels, to reduce environmental impact.

Competitive advantage: Companies that adopt sustainable electrical systems not only reduce costs but also improve their market reputation.

FAQs about Industrial Electrical Installations

1. Why is it important to automate an electrical installation?

Automation reduces costs, improves energy efficiency, and enhances safety by minimizing human errors and optimizing system performance.

2. Which companies benefit from electrical automation?

All companies with significant energy consumption, from factories to large commercial buildings, can benefit from automation.

3. How much does it cost to automate an electrical installation?

The cost varies depending on the size of the installation and the technologies implemented, but savings in energy efficiency and maintenance usually justify the initial investment.

5. What future trends are expected in this field?

The IoT, artificial intelligence, and sustainability will continue to pave the way for more efficient and intelligent installations.

We advise you

Whether you need guidance on equipment selection, process optimization or the implementation of new technologies, we are here to help you clear up any doubts you may have.

You can also visit us at: OUR INSTALLATIONS