The maintenance of industrial electrical panels is essential for the safety and efficiency of any plant. This technical guide outlines the 10 key tasks that should be carried out to prevent failures, ensure the protection of equipment, and extend its lifespan. From visual inspections to measuring electrical parameters and reviewing protections, understanding and applying these procedures is crucial to minimize risks and optimize the performance of the industrial electrical system.

1. Visual Inspection of General Condition

Effective maintenance begins with a detailed visual inspection. The following should be checked:

- The presence of corrosion on metal components.

- Overheating or discoloration on cables and connectors.

- Condition of labels and signage for regulatory compliance.

- Possible cracks or deformations in the panel.

Procedure

- Inspect each component with adequate lighting.

- Use a thermographic camera to identify invisible hot spots.

- Check that the panel covers and locks are in good mechanical condition.

2. Cleaning of Electrical Components

Accumulated dust and dirt can cause partial discharges and insulation failures. Cleaning should be thorough and done without damaging the components.

Recommended Method:

- Disconnect the panel before any cleaning.

- Use industrial vacuum cleaners with anti-static nozzles.

- Apply dry compressed air at low pressure.

- Avoid liquids and corrosive products.

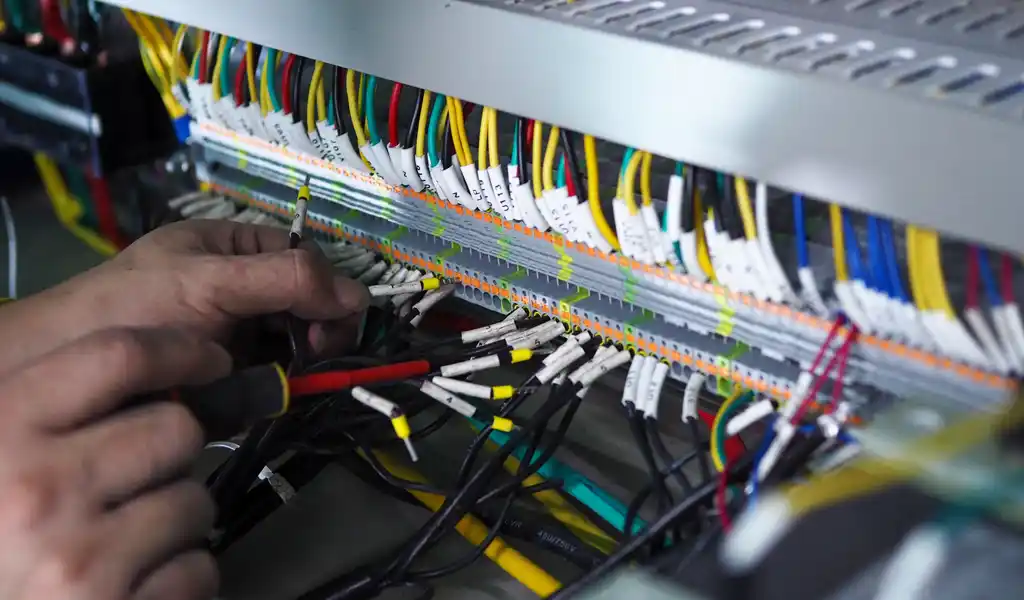

3. Tightening and Re-tightening of Connections

Loose terminals and busbars can cause electrical arcs and overheating.

Procedure:

- Use a calibrated torque wrench according to the manufacturer’s specifications.

- Inspect screwed connections and busbar barriers.

- Apply anti-oxidant paste on exposed copper and aluminum contacts.

4. Temperature Measurement on Critical Components

Overheating is one of the main causes of electrical failures.

Recommended Method:

- Use a thermographic camera to identify hot spots.

- Compare the values with those recommended by the manufacturer.

- Inspect transformers, circuit breakers, and high-load contactors.

5. Verification of Proper Ventilation and Cooling

A poorly ventilated electrical panel can cause premature failure of internal components.

Key Steps:

- Check the cleanliness of ventilation filters.

- Verify the operation of fans.

- Measure internal temperature with infrared sensors.

6. Measurement and Analysis of Voltages and Currents

Regular measurements help detect overloads and phase imbalances.

Procedure:

- Use a clamp meter on each phase.

- Measure voltages between phases and neutral with a calibrated multimeter.

- Evaluate electrical harmonics in critical installations.

7. Inspection and Testing of Electrical Protections

Protection devices must operate correctly to prevent catastrophic failures.

Key Steps:

8. Inspection and Maintenance of Grounding Connections

A faulty ground connection can cause dangerous electrical shocks and equipment failures.

Recommended Method:

- Use a ground resistance tester to measure the grounding resistance.

- Inspect the electrical continuity of the ground connections.

- Replace corroded connectors in the grounding system.

9. Verification of Communication and Signaling

Electrical panels with automation rely on stable communication systems.

Procedure:

- Evaluate the integrity of industrial network wiring (Modbus, Profibus, Ethernet IP).

- Check the status of PLC and HMI through error diagnostics.

- Measure signal quality with an industrial network analyzer.

10. Updating Documentation and Maintenance Records

Good maintenance includes detailed documentation of each intervention.

Key Steps:

- Update electrical schematics and single-line diagrams.

- Record voltage, current, and resistance measurements during each maintenance.

- Create maintenance reports with observations and recommendations.

Conclusion

The maintenance of industrial electrical panels is key to preventing unexpected failures, extending the lifespan of equipment, and improving safety. With a well-structured inspection routine, operational efficiency and regulatory compliance can be ensured in any industrial environment. If you need reliable industrial maintenance services, don’t hesitate to contact us. Our team of experts is ready to offer tailored solutions and ensure the proper functioning of your facilities.

We advise you

Whether you need guidance on equipment selection, process optimization or the implementation of new technologies, we are here to help you clear up any doubts you may have.

You can also visit us at: OUR INSTALLATIONS